Wagstaff Partners with East Valley School District

to Launch Knight Manufacturing

East Valley School District adds Knight Manufacturing course to their Career

and Technical Education curriculum - Effective September 3, 2024

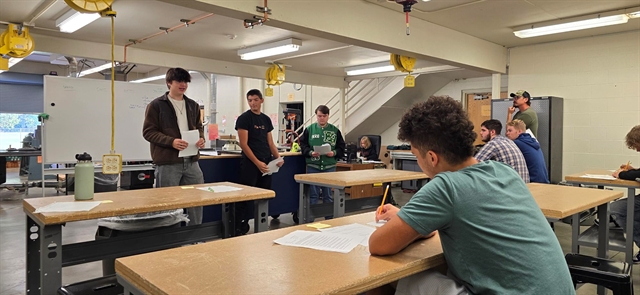

Spokane Valley, Washington— September 10, 2024 — On September 3, 2024, a partnership between Wagstaff, Inc. and the East Valley School District’s (EVSD) faculty and students added a new class to East Valley High School’s (EVHS) Career and Technical Education (CTE) curriculum. The course, named Knight Manufacturing, is a student-run business that will sell products, receive purchase orders and provide training careers in the skilled trades. There are currently 16 students enrolled in the class under the tutelage of EVHS CTE instructor Justin Sinn.

How Knight Manufacturing Came to Be

Knight Manufacturing is the result of collaborative efforts between Dr. Wade M. Larson, Wagstaff’s Director of Workforce Development, and Doug Edmonson, the EVHS CTE Program Director. Inspired by the lessons learned from five years of operating the Production and Manufacturing Institute (PMI) for high school students in the Spokane area, Larson and Edmonson travelled together to review similar education models in other states and implemented the best practices they observed into Knight Manufacturing.

Dr. Larson also acknowledged EVSD Superintendent Brain Talbott for his commitment to this new course, and for his efforts that resulted in doubled enrollment in the EVHS CTE program in the past year. Talbott has also been instrumental in expanding PMI, and his efforts resulted in obtaining a $200,000 grant to update the shop classrooms and facilities at EVHS. His support makes a dramatic difference in fostering the strategic partnership between local business and education.

A Glimpse Into the Knight Manufacturing Syllabus

Knight Manufacturing’s first classroom group is operating under a business plan that models a start-up funded by an investor. Students will immediately begin learning business operations, gaining new skills, and identifying products to design and manufacture. They will also design sales systems and create point-of-sale processes that will allow them to begin taking orders from real customers. As the students establish their initial plan and gain on-the-job knowledge, they will lay the foundation for future Knight Manufacturing students and educators.

Knight Manufacturing Would Not Have Been Possible Without Generous Sponsors

Wagstaff and the East Valley School District would like to thank their partners who helped make Knight Manufacturing a reality. PMI sponsors such as MacKay Manufacturing, Pearson Packaging Systems, Collins Aerospace, Career Connect Washington, and the Spokane Workforce Council established a solid foundation for this class. Other sponsors including Kaiser Aluminum, BECU, The Machinists Institute, the Krumble Foundation, the Greater Spokane Valley Chamber of Commerce, and Parker Hannifin have supported key components of this educational program. HOTSTART, Sonderen Packaging, NIMA, and KXLY TV have helped support the overall costs associated Knight Manufacturing and other learning opportunities. Support from Advanced Thermoplastic Composites, Inc, Idaho Central Credit Union, ALTEK, Merkle Standard, ControlFreek Inc., and the Pacific Northwest Chapter of Associated Builders and Contractors has been instrumental in assisting this educational mission. Community Colleges of Spokane, North Idaho College, and NEWESD 101 (NorthEast Washington Educational Service District 101) have provided educational partnerships and are major supporters of this and other career pathways.

For More Information, Please Contact:

Wade Larson

Phone: 707.290.9121

Email: wade.larson@wagstaff.com

Wagstaff Announces CEO Transition

Kevin Person announces retirement; Steve Anderson appointed Chief Executive Officer, Jack White promoted to Vice President of Sales and Marketing - Effective April 1, 2024

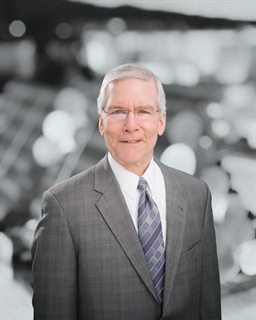

Spokane Valley, Washington — March 15, 2024 - Wagstaff Inc.’s Board of Directors has announced that Kevin Person, current Chief Executive Officer will retire effective March 29, 2024. Person has served as the company’s CEO for the past 13 years. Steve Anderson, Wagstaff’s current Vice President of Sales and Marketing will succeed Person in the role. Anderson has been with the company since 1995.

Person’s contributions to Wagstaff and the Spokane area light metal industry

Person’s contributions to Wagstaff and the Spokane area light metal industry

Kevin Person’s name has been synonymous with aluminum production in Spokane for almost a half century. Prior to joining Wagstaff he was with Kaiser Aluminum for 21 years. During his 25 years at Wagstaff, Person has also held the titles of Vice President of Sales and Marketing and Application Engineering Manager. Person’s leadership tenure has included record sales and revenue and significant expansion to Wagstaff’s Spokane campus, all while deftly navigating the serious challenges posed by the 2008-2009 global financial crisis and the COVID pandemic. Person also assisted in expanding the scope of Wagstaff’s business from direct chill casting to the nuclear industry. We sincerely thank Kevin for the years of outstanding leadership, counsel and stewardship and the excellent value he brought to Wagstaff. We wish nothing but the very best for Kevin as he begins his well-deserved retirement.

Anderson begins third decade with Wagstaff as CEO

Anderson begins third decade with Wagstaff as CEO

Having earned degrees from Washington State University in both Electrical Engineering and Business Management, Steve Anderson arrived at Wagstaff in 1995. Anderson has held many engineering positions with Wagstaff across several departments (Research and Development, Automated Services Group, Applications), and honed his management acumen by serving as ASG Engineering Manager, R&D Automation Manager, and Director of Engineering. In 2016 Anderson was promoted to his current role of Vice President of Sales and Marketing.

Steve’s breadth of education and work experience have provided him the opportunity to not only develop his leadership skills, but additionally to see and understand the organization from numerous internal perspectives. We look forward to Steve applying those strengths and abilities to his new role and look forward to continued success for Wagstaff under his leadership.

White continues Wagstaff career with promotion to VP of Sales and Marketing

White continues Wagstaff career with promotion to VP of Sales and Marketing

After serving as Wagstaff’s Applications Engineering manager for the past 16 years and performing a dual role as the Area Sales Manager – Western United States for the past four years, Jack White has accepted the opportunity to become the company’s next Vice President of Sales and Marketing. White, who holds a degree in Mechanical Engineering from West Virginia University also has 39 years of experience in the aluminum industry to draw on in his new role.

During Jack’s time with Wagstaff he has travelled literally millions of miles around the globe evaluating countless casting pits with the goal of incorporating Wagstaff casting solutions into those facilities.This deep understanding of our customers and their needs are a resource that will strongly inform the decisions he makes as he leads the Wagstaff Aluminum Sales Group in the coming years.

Media Contact:

Meng Yu

Wagstaff, Inc.

Phone: 509-891-8058

Email: meng.yu@wagstaff.com