WAGSTAFF BILLET MOLDS: TAILORED TO SUIT YOUR PRODUCTION GOALS:

Please wait while we gather your results.

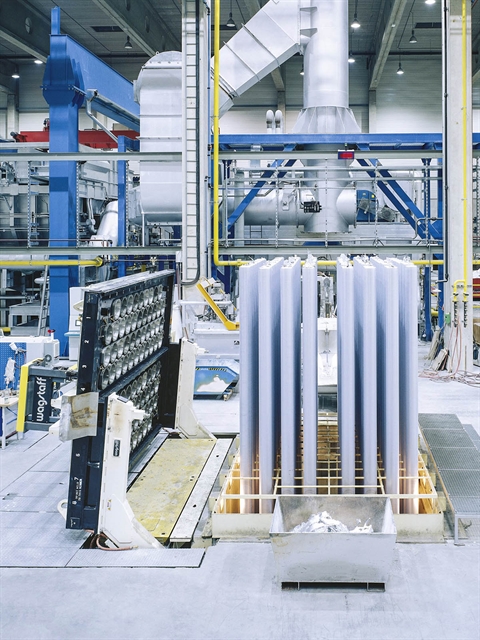

AirSlip Billet Casting

The Wagstaff® AirSlip® Air Casting Technology produces the highest quality billets, known for their smooth surface finish, small shell zone, and uniform-grain structure — the world standard for billet quality.

Read More...

NuMax Billet Casting

The Wagstaff® NuMax™ Billet Mold technology is second in product quality only to the AirSlip® Air Casting Technology.The key advantage to NuMax technology is that it offers significantly improved productivity to the billet producer while reducing maintenance time and costs.

Read More...

ARC Large Diameter Billet Casting

Wagstaff® ARC™ Technology utilizes a combination of refined casting recipes, an advanced mold design, and features developed distinctly for aerospace and common alloy aluminum billet casting in large diameters greater than 520mm.

Read More...