QUALITY PRODUCTS & LEADING EXPERTISE.

Please wait while we gather your results.

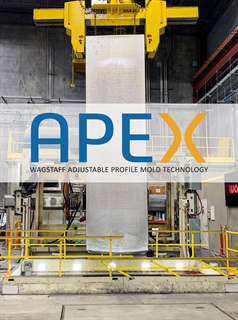

APEX™ Ingot Casting Technology

The Wagstaff® APEX™ Rolling Ingot Casting Technology incorporates a fully automated, fully adjustable mold that all but eliminates ingot butt swell.

Read More

AutoCast™ V

The Wagstaff® AutoCast™ V system includes state of the art hardware running custom software designed specifically for controlling and optimizing the direct chill casting process.

Read More

Aerospace Ingot and Billet Casting

Wagstaff® Aerospace Hard Alloy Casting Technologies comprise advanced, specialized systems designed specifically to cast strong alloys for aerospace, military, and commercial applications.

Read More

Billet Casting

The Wagstaff Billet Casting System is the core of a successful extrusion billet casting operation. The options are virtually endless, with diameters available from 110 to 1233 mm, and strand counts from 1 to 160 billets per drop. Wagstaff has been designing custom billet solutions for more than three decades, and has built more than 1,100 systems to date.

Read More

Ingot Casting

With more than 50 years of experience providing tailored ingot casting solutions to aluminum industry, Wagstaff's reputation is rooted deep in innovation and reliability for rolling ingot casting. Casting beverage can, aerospace body, or building façade stock is possible via the infinite number of options in ingot size, alloy, technology, and technique.

More ingot producers choose Wagstaff ingot technology than any other direct-chill casting equipment in the world.

Read More

Casting Machines

The Wagstaff® ShurCast™ system is designed to provide improved productivity and high quality straight products. There are 10 scaled cylinder models available according to cast load needs. ShurCast Casting Machines are manufactured to exacting tolerances to provide flawless performance, cast after cast.

Read More

Automation

The Wagstaff® AutoCast™ Automated Casting Control System monitors and controls crucial parameters to eliminate variances in the complex casting process. Your casting operations can achieve precise and repeatable measurement and control to produce a more consistent, quality end product. Wagstaff integrates years of process expertise with high quality, industrially proven control devices and technologies into the AutoCast control system to create an environment of repeatability and consistency in the casthouse.

Read More

Mold Table Mounting Systems

The Wagstaff® Mold Table Mounting System provides rigid mounting support for the mold table. Each system is specifically designed and engineered to fit existing or newly ordered mold tables. Several types of mounting systems are available depending upon customer needs and casthouse requirements.

Read More

Trough Metal Level Control

From automated systems to simple mechanical devices, Wagstaff offers a metal level control technology to suit your needs.

Read More